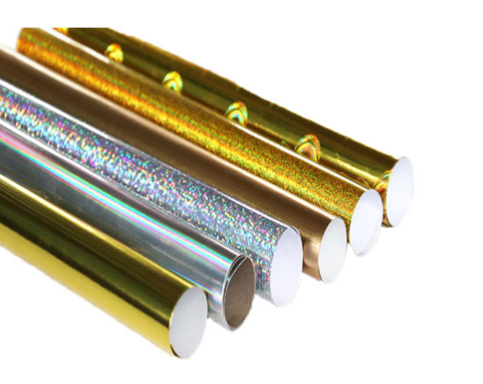

In some applications, metallized paper is intended to replace metallized film for environmental and cost efficiency reasons. In order to help customers take full advantage of metallized paper, we will further analyze the structure of metallized paper in the hope that it will help customers to get the ideal packaging.

The following shows the detailed structure of metallized paper, from the inside to the outside of each layer as follows.

Clay coating

Raw paper

Pre-metallized coating

Aluminum metallization layer

Printed surface primer

Raw paper is usually made from vegetable fibers and the pulp is mixed with fibers of different lengths, so when it dries into a paper substrate, the surface is rough with dents and bulges, which will result in a poorer rendering of the artwork for printing than a smooth surface. Therefore, in order to obtain a smooth surface with good wetting tension, clay coatings are often used.

Clay coating can be applied on one or both sides of the original paper, it usually depends on the final application, as shown in the figure below, clay coating will obtain a smoother surface for further printing and coating operations.

Pre-metallized coatings act like anchors to improve the bond strength between the aluminum metallization layer and the paper substrate, which is usually achieved prior to the metallization process.

The thickness of the aluminum metallization layer is only 30-50 nm, which is only 0.04-0.07% of the paper substrate thickness, so the thickness of the aluminum metallization layer can usually be ignored when evaluating the thickness of the metallized paper. However, this aluminum metallization layer does play an important role in printing and packaging applications.

Another top coat is applied over the aluminum metallization layer, usually as a protective layer. When metallized paper is used for printing beer labels, it is usually printed on the surface of the aluminum metallized layer, but the aluminum layer can be damaged by water in water-based inks. This is the reason why a varnish layer is needed.

The unique HD finish is the main advantage of printing on metallized label stock. In addition to this, there are several other benefits.

As the image is infused into the metal surface, it produces a clear and vibrant finish that really shows off the beauty of the photo.

Two finishes are available (gloss and matte), which makes this medium suitable for all tastes and preferences.

Custom metal prints feature a clean, frameless design that minimizes the hassle of framing under glass or acrylic.

The frameless design also means no additional framing costs. You don't need to invest in additional accessories to display them.

Metal is a very durable material that will keep your artwork looking just as good for years to come.

Metal prints are waterproof and scratch resistant, which further extends their life and makes them very easy to maintain. Smudges and fingerprints can be easily wiped off with a damp cloth without worrying about damaging the print. This also makes them more versatile as they can be displayed in the kitchen, bathroom or even outdoors.

Well, that's all YF has to say about the structure and benefits of metallized paper. Next I will cover more about the applications of metallized paper. If you have any questions, please feel free to contact us if you want to customize a unique looking label for your brand.

Copyright © HUBEI Y.F PACKAGING MATERIALS CO., LTD. All Rights Reserved | Sitemap

| Powered by

Recommend Products: Pressure Sensitive Paper Beer Label Paper Water Resistant Paper for Labels What are the different types of holographic paper?