Technical Indicators

Label Paper - Related Technical Requirements

| Manufacture→ | Printer→ | End User | ||||

| ■ Base papern ■ Coatingn ■ Finishingn ■ Embossing | ■ Printability ■ Surface ■ Runability ■ Flatness ■ Varnishing ■ Trimming ■ Die-cutting | Visual ▶ Brightness ▶ Gloss▶ Opacity ▶ Wet opacity ▶ Embossing | Labelling ▶ Wet strength level ▶ Tensile strength▶ Glue absorption ▶ Label “setting” ▶ Rub resistance | Bottle cleaning ▶ Alkaline resistance ▶ Wet strength level▶ Wash off time ▶ Ink retention ▶ COD ↓ ▶ Recycling | ||

Quality control – Physical properties, Printability, Converting

● Substance ● Calliper ● moisture content ● ash content ● Formation ● curling tendency / flatness ● pick resistance ● ink retention ● Mottling ● helio test (rotogravure) ● Varnishability | ● Brightness, shade ● Smoothness of coated side and reverse side ● Gloss ● Opacity under dry and wet state ● Tensile strength under dry and wet state ● Stiffness, dry and wet ● Die cutting properties ● Lab metallisation |

Printing Process – Influences

● curling tendency / flatness ● pick resistance ● ink resention ● Mottling ● helio test (rotogravure) ● Varnishability ● Die cutting properties | ● Smoothness of coated side and reverse side ● Tensile strength ● Wet strength level ● Elongation in wet environment ● Printability in offset, rotogravure and flexo ● Rub resistance (under wet and dry) |

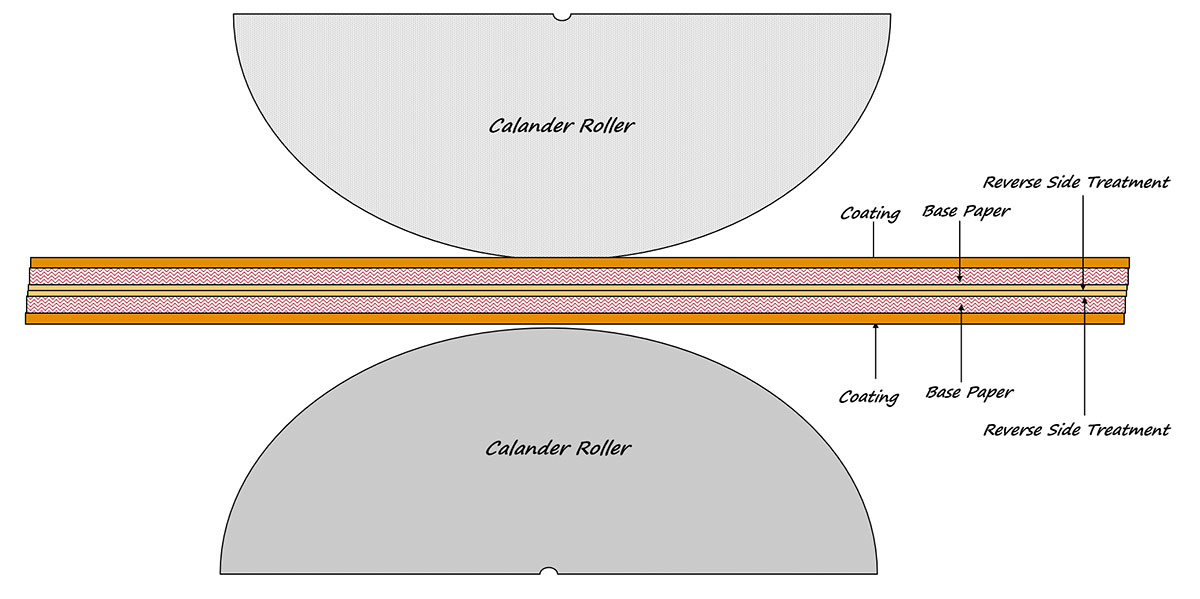

Matt Reverse Side by Double Web Calandering

Reverse Side -

Main Properties – Treatment

Rough reverse side:

● Advantageous with respect to sheet separation and ink drying.

● Highest reliability, needs something more glue

Reverse side treatment

● Curling tendency / flatness

● Separation in printing process

● Flatness under changing climates

Labelling Process – Influences

The Labelling Process is complex and consequently influenced by many factors:

Paper characteristics

Embossing

Varnishing

Metallised Paper

Printing

Label design (shape and size)

Container form / material

Container surface / temperature

Glues

Storage of labels

Preparation of labelling machine

Filling / Labelling condition (temperature, moisture)

Wet Glue Label Papers

Most important Properties

• Wet tensile strength during labelling process

- Glue absorption

• Wet Opacity

- Condensation due

to cold bottle surface

• Alkaline resistance

• Ink retention

Influenced by paper characteristics

● Water absorption

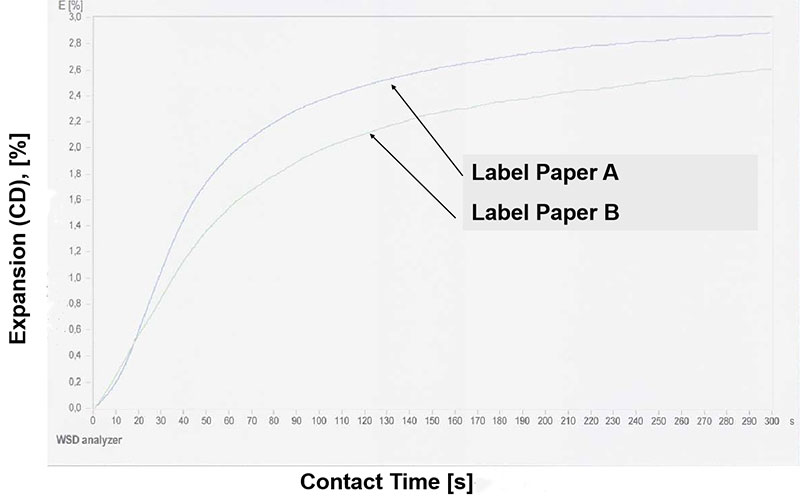

● Dynamic Wet stretch

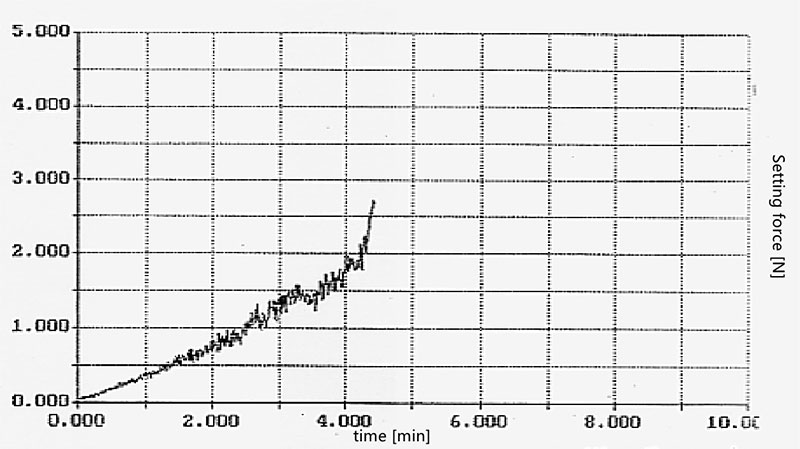

● Glue setting speed

● Glue absorption

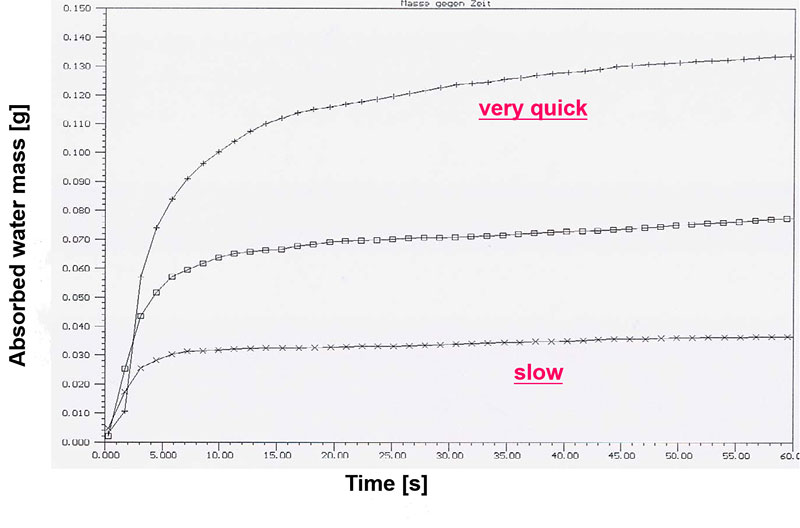

Cobb value - water absorption

1) Low Cobb value: <12 g/m²

▶ No wrinkles, but possibly flagging and “falling off” labels

2) Medium Cobb value 12-17 g/m²

▶ Highest reliability in performance

3) High Cobb value >17 g/m²

▶ No flagging , but possibly wrinkles

Water absorption (reverse side)

Dynamic Wet Stretch (elongation)

Glue setting speed

Quality Control – Special tests for Label Papers

Alkaline penetration

Alkaline resistance

Wash off time / wet strength level

Ink retention

Wet rub resistance

Glue setting speed

Glue absorption

Wetability of reverse side

Ink adhesion in alkaline solution

Rub resistance (wet and dry)

Wet stretch

Water absorption (Cobb value reverse side)

Dynamic water penetration

Opacity, dry and wet

Tensile strength, dry and wet

Stiffness, dry and wet

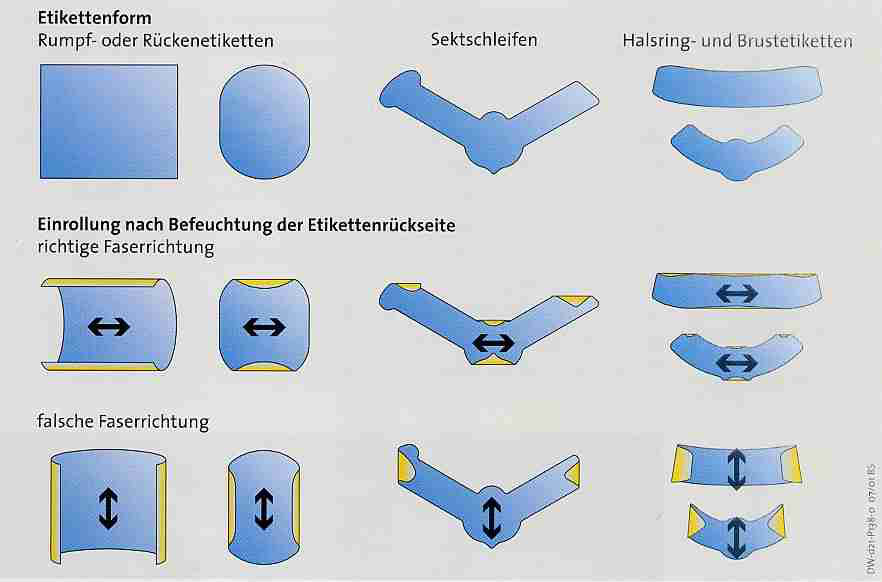

Curling tendency / flatness

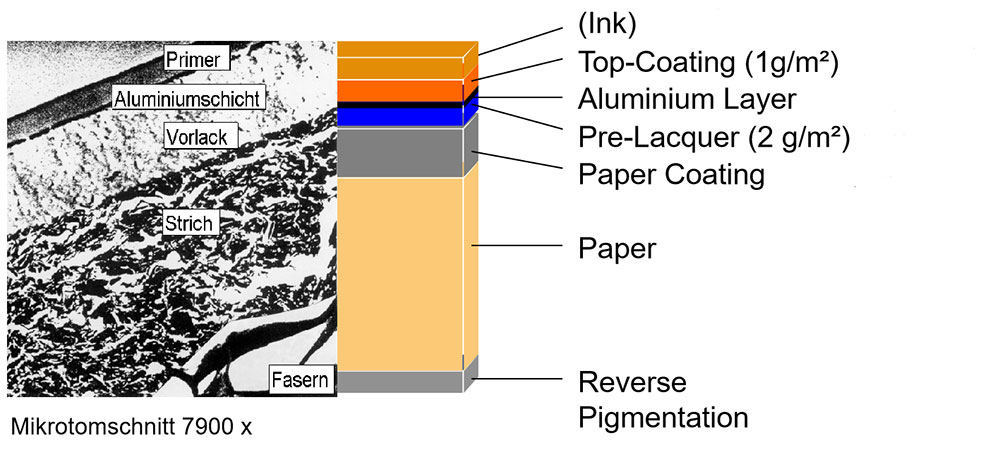

Structure of metallised paper

Influenced by metallising and printing

Wet curl force

depends on:

Base paper

Printing

Varnishing

Pre-lacquer

Primer

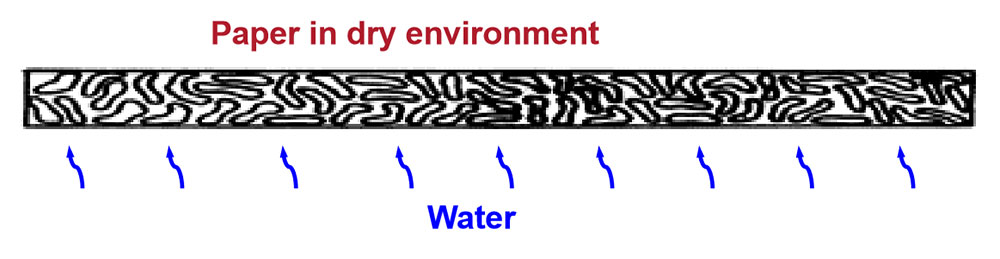

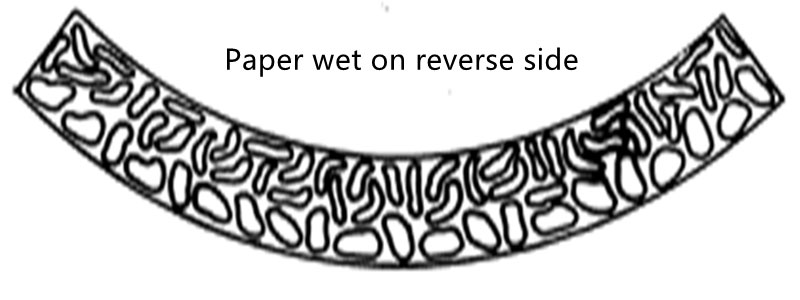

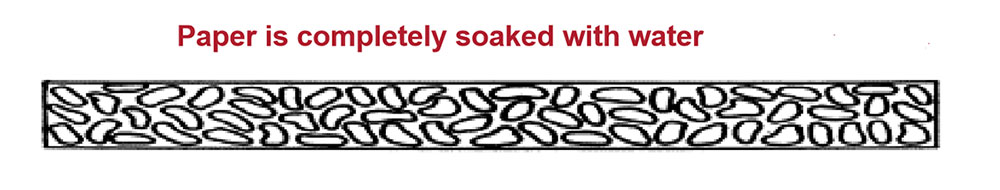

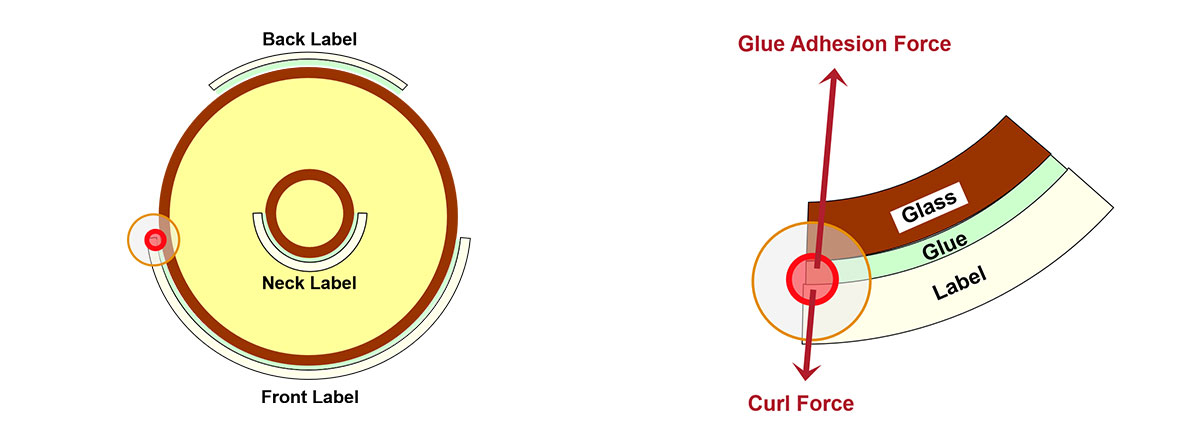

● Fibres expand primarily on the reverse side, therefore paper curls to front side.

● Tack of glue must be higher than curling force of the label.

● Fibres expand primarily on the reverse side, therefore paper curls to front side.

● Tack of glue must be higher than curling force of the label.

● Fibres expand primarily on the reverse side, therefore paper curls to front side.

● Tack of glue must be higher than curling force of the label.

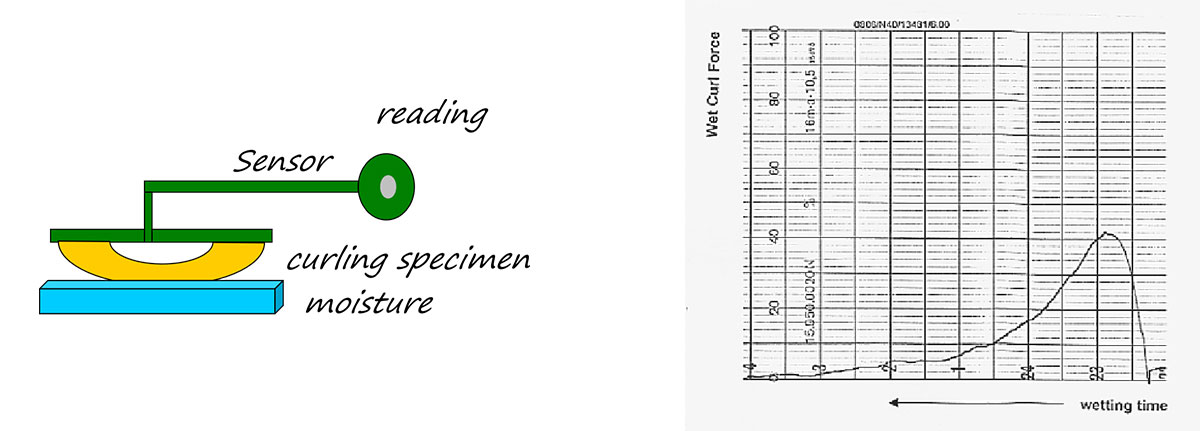

Measurement of wet curl force

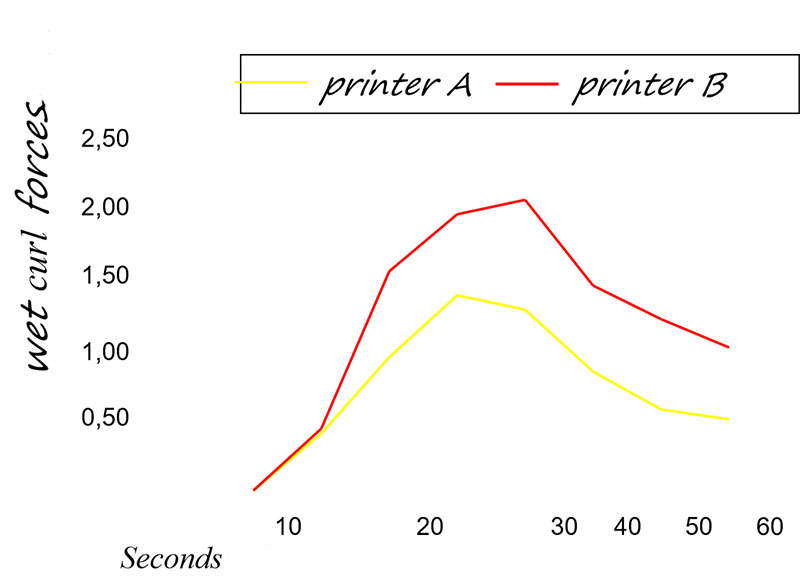

Diagram of wet curl forces

paper, metallizer, label = identical

Wet curl

Corect Fiber Direction

Influenced by Glue

Temperature

Type of glue - Casein / non Casein (synthetic or dextrin)

Amount of glue

Viscosity

Tack

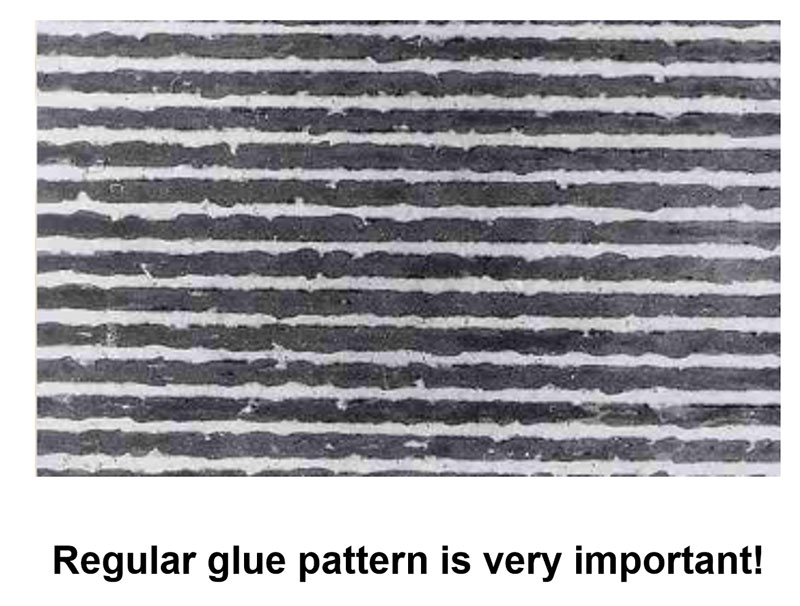

Glue Pattern

Influence Factor Container Design

● Glass/PET

● Surface treatment – Water- repellent surfaces

● Noncircular bottles and jars

● Used bottles (abrasion)

Influence Factor Labelling Machine

● Pressure between Glue Roller and Glue Pattern

● Pressure between Glue Pattern and Label

● Amount of Glue

● Speed

● Even glue distribution / Even Glue Pattern structure

Copyright © HUBEI Y.F PACKAGING MATERIALS CO., LTD. All Rights Reserved | Sitemap

| Powered by

Recommend Products: Pressure Sensitive Paper Beer Label Paper Water Resistant Paper for Labels What are the different types of holographic paper?