Specialty papers are papers with special uses and relatively small production volumes. Special paper is a wide variety of special-purpose paper or art paper collectively, and now sellers will be embossed paper and other art paper collectively referred to as special paper, mainly to simplify the variety and confusion caused by the terminology. Manifacturer YF shows you.

There are more than 550 paper machines worldwide - often smaller in output and size than regular paper machines - used to make specialty papers.

More product companies are exploring ways to enter the specialty paper business. Commodity paper mills or newsprint mills in these regions have converted - often at high cost - to specialty paper production. New chemicals and improved process technology are allowing wider and faster machines to produce specialty paper products more economically than traditional small specialty mills.

New product development in food contact applications continues to focus primarily on the commercialization of water-based barrier coatings to replace expensive and environmentally controversial fluorocarbons. Major chemical companies have been seeking a variety of proprietary innovative solutions to give paper environmentally friendly water resistance properties.

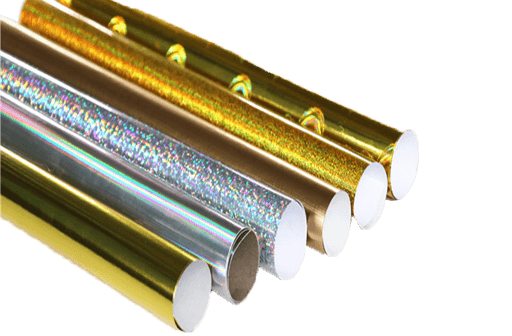

Wet-strength papers were so developed, and thanks to a blend of wet-strength agents, they stand up well to wet conditions without breaking. Wet-strength holographic metallized paper is a base to which one adds a metallic film to reflect the metallic glow. These papers are widely used in packaging labels for food and beverages.

Flexible packaging continued to be the largest segment in terms of sales over the last year, with environmental regulations supporting this growth and new opportunities presented by stricter waste packaging requirements in many EU-led regions. In some areas, the switch from plastic to paper will continue to accelerate - for example, the recent ban on plastic straws in some U.S. cities.

Machine-glazedpaper is widely used for laminating, coating, metallizing and converting into a variety of flexible packaging materials. The existing volume is large and growing steadily. Although wax paper is relatively low cost, it is losing market share as some traditional applications now use products with better barrier properties.

The explosion in Internet shopping and related product shipping has driven a corresponding increase in thermal transfer, direct thermal and digitally printed shipping labels. Government regulations regarding product safety continue to drive the growth of ingredient, safety warning, shipping hazard and health warning labels.

For labels, plastic film facestock has gained market share in some applications because of its flexibility, durability and moisture resistance - but paper is still very common in most applications.

Please contact us today to get more details and we'll do our best to help you.

Copyright © HUBEI Y.F PACKAGING MATERIALS CO., LTD. All Rights Reserved | Sitemap

| Powered by

Recommend Products: Pressure Sensitive Paper Beer Label Paper Water Resistant Paper for Labels What are the different types of holographic paper?